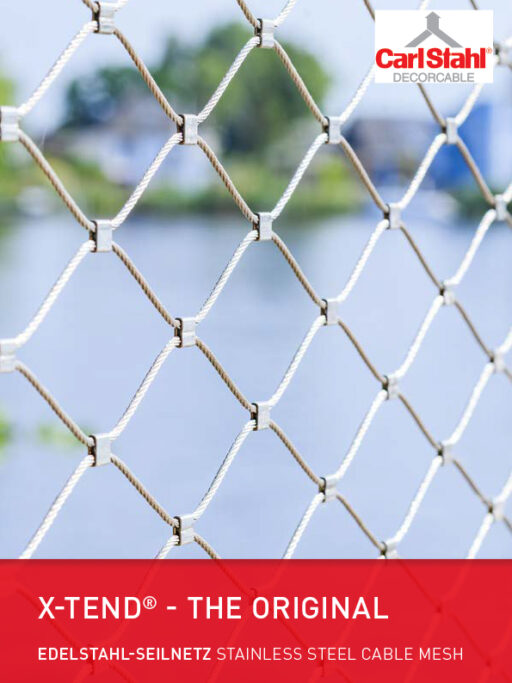

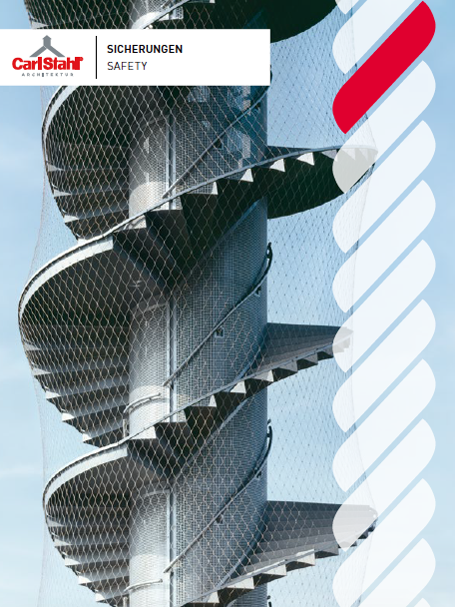

Cable mesh is increasingly opted for as security in or around a stairwell. It is an economical and sustainable solution because virtually no steel work is required. Major advantages compared to other materials are the high transparency and the light construction that is required. The industrial and modern "look" complete it. In general, a cable mesh net from the top to the bottom floor can consist of one piece.

safety mesh -

vertical.

industrial

modern

look.

material.

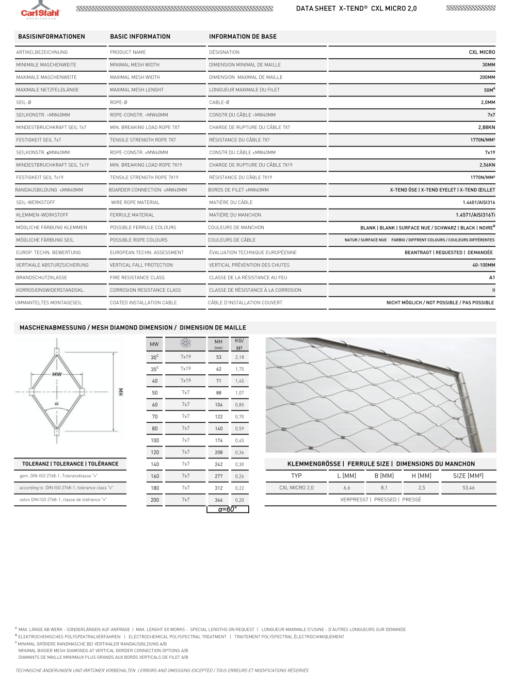

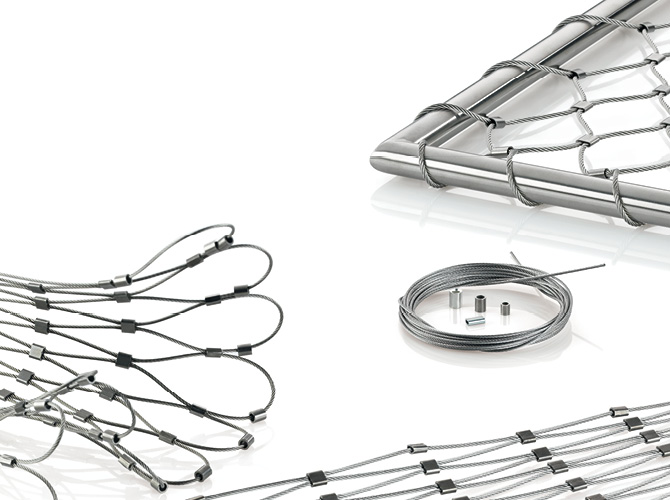

The cable mesh is made of stainless steel AISI316 (also known as 1.4401 or A4 quality). We can guarantee this quality 100% through European certificates. For this application, this steel quality is technically the best solution for price and delivery time.

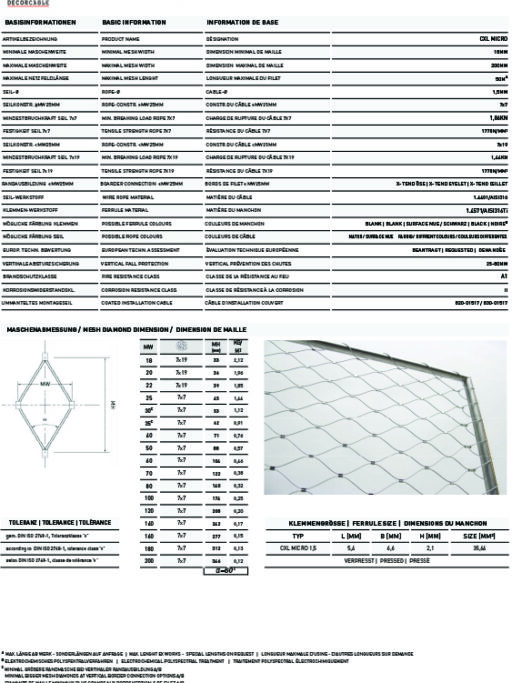

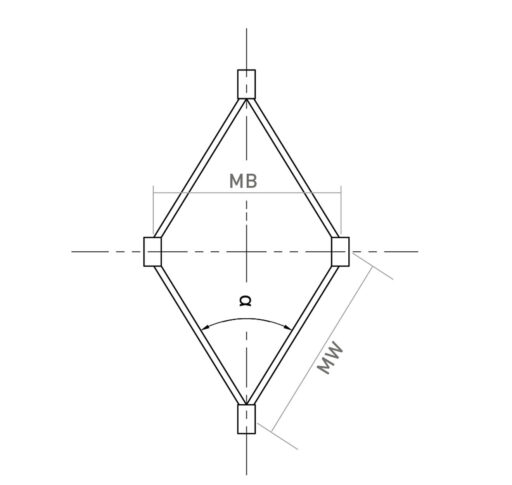

mesh size.

The size of the openings in the mesh is also referred to as the diamond size. A diamond size of 60mm is generally used in stairwells. The diameter of the cable is usually 2mm. Other mesh sizes are also possible, but not common in stairwells.

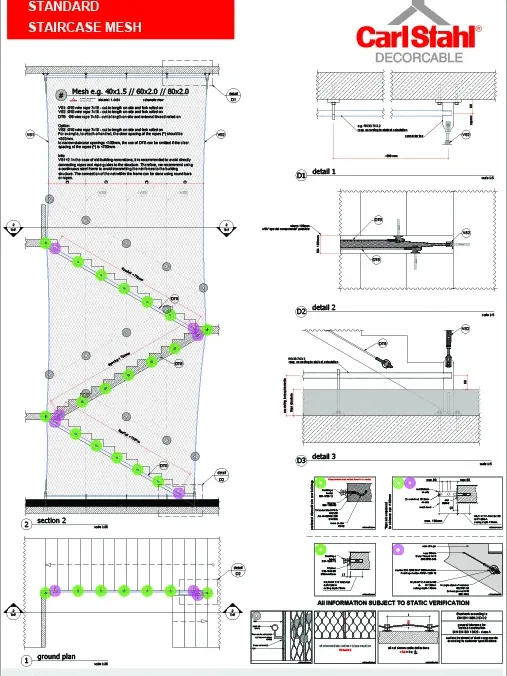

details.

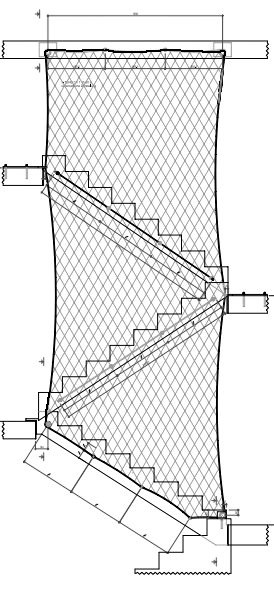

Cable mesh can be used in various ways in stairwells. Depending on the width of the stairwell compartment (or void), it must first be determined whether it will be a single, a double or a revolving net. In addition, you can choose to tension the mesh between a border cable or a tubular frame. Different scenarios are also possible at the top and bottom of the stairwell. View a number of options below.

single net.

double net.

circular net.

border cables.

The mesh is usually stretched between a border cable. The border cable is guided through eyes on the landings and the floor edges. This is the most transparent way of detailing. The eyes are chemically anchored in the concrete or, if possible, anchors are included in the stairs and landings.

border tube.

Pendulum rod can be welded directly to the steelwork and powder coated together with the construction. This creates a tight detailing and the nets can be ideally attached to this. This detailing accelerates the assembly time on site. This is also suitable to prevent finger entrapment.

edge of cable in combination with duct.

From an aesthetic or constructive point of view, the circumferential tension cable can be guided through eyes on a rigid edge construction. In general, box or U-profiles are used with a grommet every meter. The sagging of the circular cable is then more visible.

each application is unique.

The stairwells in which the mesh is used are almost always unique in size. Every stairway compartment is slightly different, but due to the flexibility of the cables, every stairwell can be secured with tension cable mesh. Applications apply to both new and existing stairwells.

forces.

Our cable mesh is strong and can withstand great forces. For example, a line load of 3kN is no exception for our cable mesh. The mesh is resistant to leaning, kicking and climbing. All loads are generally transferred to the edge structure.

The cable mesh is tensioned on the cables with a pretension of approx. 30 to 40 kg per meter. The border cables also have a certain pretension. The magnitude of this bias is partly determined by the center-to-center distance of the lead-through eyes and the desired sag of the edge cable between those eyes.

If a person (or another load) pushes or falls against the mesh, the forces are transferred via the edge construction to the attachment points. It is important that the fastening eyes are strong enough to absorb the forces. Furthermore, the fastening components must be able to transfer the forces to the constructive columns, walls and floors.

Our team can help you further with the detailing of the mesh. If necessary, our engineers will perform static calculations.

The cable mesh is tensioned on the cables with a pretension of approx. 30 to 40 kg per meter. The border cables also have a certain pretension. The magnitude of this bias is partly determined by the center-to-center distance of the lead-through eyes and the desired sag of the edge cable between those eyes.

If a person (or another load) pushes or falls against the mesh, the forces are transferred via the edge construction to the attachment points. It is important that the fastening eyes are strong enough to absorb the forces. Furthermore, the fastening components must be able to transfer the forces to the constructive columns, walls and floors.

Our team can help you further with the detailing of the mesh. If necessary, our engineers will perform static calculations.

installation.

The installation of the stainless steel cable mesh in stairwells is usually done by a general contractor. Preparatory work and measuring will need to be done, followed by assembly of the tension cables and the mesh. It is important that clear working drawings of the stairs and stairwell compartment are available.

prices.

The cost of our X-TEND® stainless steel mesh depends on factors such as diamond size, cable diameter, shape, and overall quantity. Contact us for current pricing options.

delivery times.

Delivery time on the X-TEND® depends on the type of mesh, complexity, and overall quantity. Lead times vary from stock to several weeks. Call or email us for a more specific lead time.

quotes.

Every project is unique. Our sales team can prepare a quotation for your specific application. Please contact us to discuss your project. We will be happy to assist you.

great things

are built

with the best materials.– Carl Stahl

contact us.

Contact us for specification assistance or to request a quote. You may attach project drawings in the contact form.

Call us at +1 (312) 474-1100 Monday through Friday between 8:00 a.m. and 4:00 p.m. CST or email sales@decorcable.com. We will be in touch as soon as possible.

Call us at +1 (312) 474-1100 Monday through Friday between 8:00 a.m. and 4:00 p.m. CST or email sales@decorcable.com. We will be in touch as soon as possible.